The bottom hinge of my shower cabinet door is broken. Can’t buy a replacement because it’s too old. I think about design it and print in metal. Or to sawing and filling it out of a metallic block.

I‘m not sure how stable a metallic print is. The glass door is quite heavy either around 15 kilos. Do you guys have recommendations?

And do you know a metallic print service in Germany or Europe? I own just a plastic printer

3D printed stainless steel is pretty strong. Depending on the design of the hinge it may also be possible to have it CNC machined.

CNC machining is going to be incredibly expensive for this sort of part.

Metal 3D printing is also very expensive. Unless your talking about plastic impregnated with metal, in these cases the plastic is responsible for the structure of the part the metal is just aesthetic.

Any idea about the costs for a 25x25x50mm size? Cnc and laser sinter?

Haven’t thought about CNC yet. Thx

Once you have the model you should at least get a quote from a machine shop. 99% chance it’s way too expensive, but you never know and quotes are free.

I‘ll try. Thx

Its probably the easiest to buy another hinge for glass that doesnt require holes on glass like

Then mount it above the broken hinge.

I think metal printing and/or CNC machining could be way over expensive, but please let us know the price if you go that route. If you really want to solve this with 3D printing consider printing it from plastic and reinforcing it with steel (wire, screws, tube, or reuse existing hinge parts), but it will never look good as if you buy a hinge

Another options is to weld the existing hinge

Tried this path already. I found no potential alternative hinge. Thx

Hinges are often made of sheet metal.

This can be cut, drilled and bent to fit. A vice, a drill, a file, a hammer and hacksaw would be enough for most hinges.

If the door remains suspended with just one hinge a plastic one may work for a short while. The hinge only suspended half the load.

You can also print the hinge with a high infill percentage to improve strength and resist deformation.

I thought this version as well at first. Unfortunately, I found a detail that is sort of cogwheel effect - keeps back the door from swinging and closing. It will be very very hard to get this one drilled with a drill machine.

So, when you say ‘metallic print’? do you mean something like direct metal laser sintering (powder bed and lasers melting to make a solid part,) or the makerforge FDM printers that then sinter the part?

Either of those two will provide a more-than-adequate solution.

If you mean the metal-filled plastics (like Protopasta metal fills,) the weakness is in the plastic- and are comparable to whatever base plastic they use. Though, the iron fill and copper/brass/bronze fills all are high enough in metal content they can corrode as well as take most of the polish with, so they’ll age. the metal is purely cosmetic, though.

the plastic holds up well enough, and how much of a patina they get depends on some factors, but it’s only the surface that gets the patina- the iron fill, for example won’t rust all they way through. The polish is nice, and you can age them (a weak solution of water and vinegar, for iron, as an example,).

If you can print PLA hinges that hold up well, you can expect roughly the same performance, and the only real change you need to make for metal fills is going to a hardned nozzle. Given the structural concerns, I would suggest looking for metal-filled ASA, or similar rather than PLA fill and testing the prints with regular plastic first- metal fills are relatively expensive, after all.

Thanks for that thorough answer. Yes, I thought of the laser sintering thing. The glass door is quite heavy. I diubt plastic prints with some aesthetical metallic cover can hold it. I mean, the hinge was broken because of the weight and calcification.

Do you have an idea how much laser sintering might cost for a 25 x 25 x 50 mm size? Printing it first in plastic as a prooftest is a good idea.

I’m not sure on costs, and that depends a bit on material. I know ProtoLabs has a German location.

They do good work but aren’t cheap.

Thx. I‘ll check them as well.

I would model the part myself, print it myself and check for fit and function. Once the part design and tolerances confirmed, I would then either use a local or remote shop.

Xometry.eu (no affiliation, never used them) appears to be in Europe and outsources to local shops. They have plastic and metal SLS, CNC, sheet metal, and everything else as possibilities. https://xometry.eu/en/direct-metal-laser-sintering/

Another option is to use the Chinese PCB shops. PCBWay has amazing abilities these days: https://www.pcbway.com/rapid-prototyping/manufacture/?type=3&reffercode=TOP

Do you have any pictures of the broken part?

Get a metal bar, bend it like the sketch I did and drill the corresponding holes. You could 3d print a rectangular spacer to stop the pin holding part from compressing in use.

deleted by creator

TIL: One can upload pics in my Memmy app.

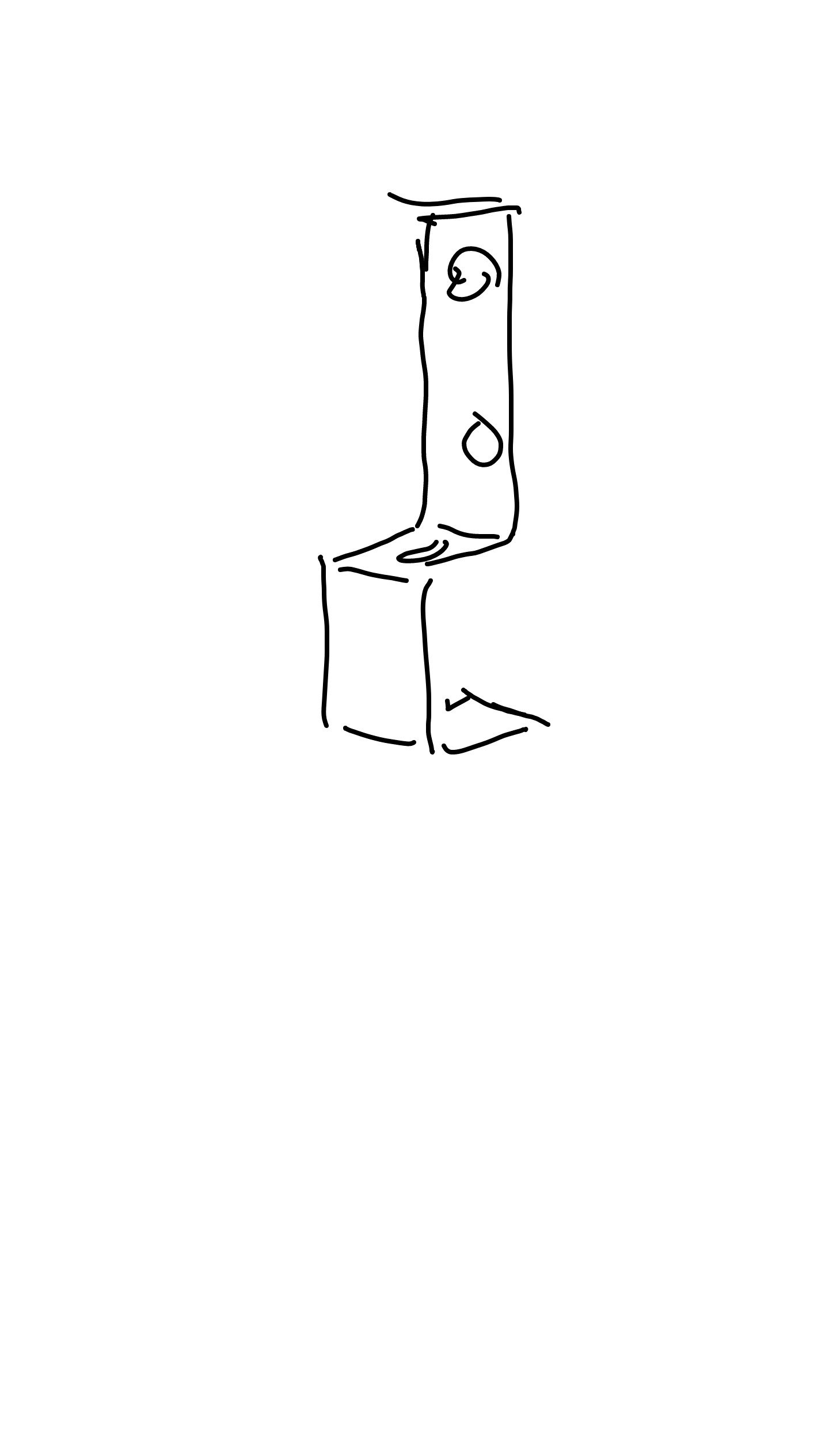

One pic is the broken part of the hinge. It was broken at the area of the headless screws (used to fix the iron joint pin). There is a hollow box in the metal. I think the combination of headless screws and hollow box is the reason for the damage. Simply to less material.

One picture where you see a proper hinge with all parts. The part at the wall is the broken one.