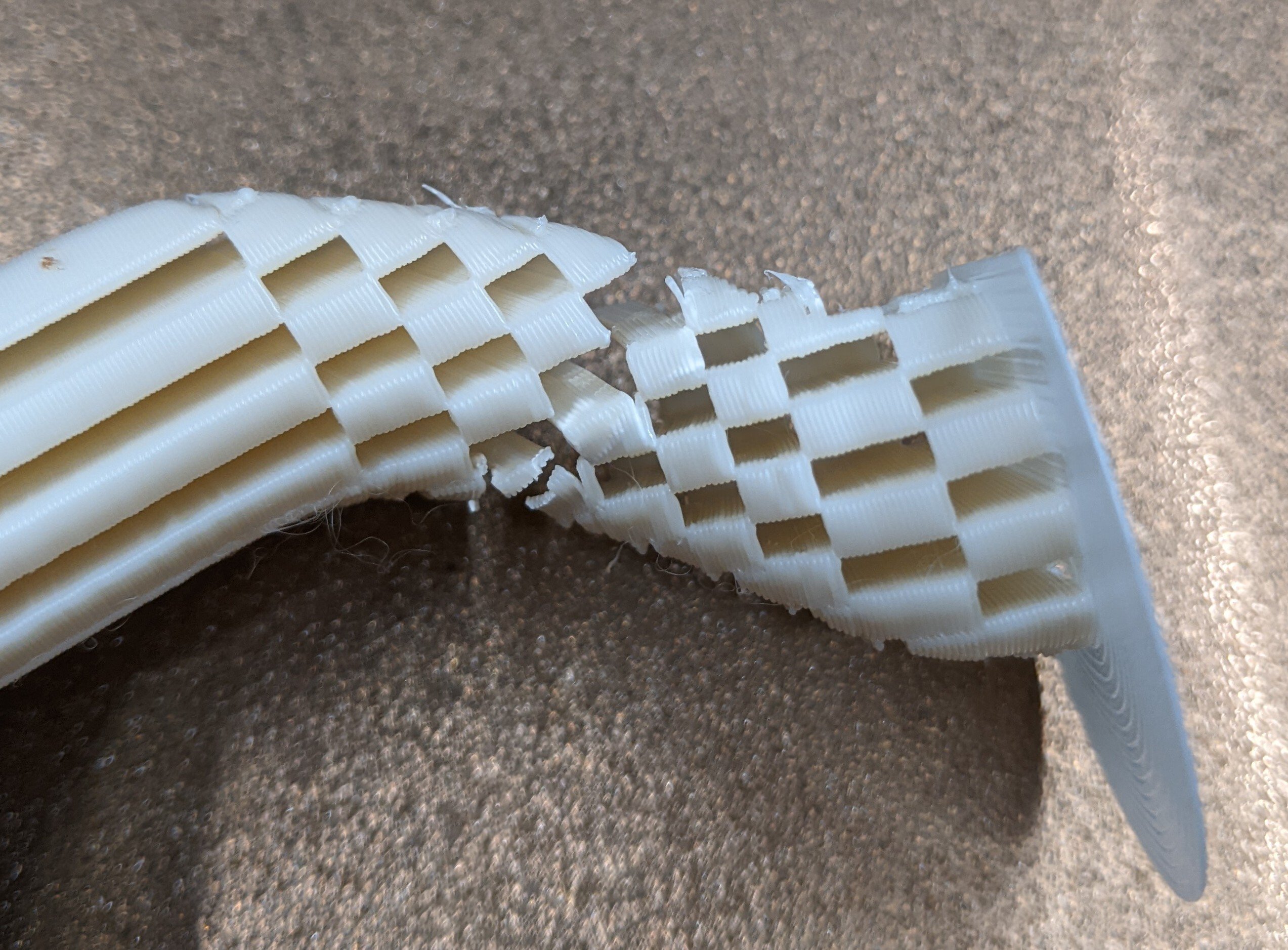

At least so far. The first go round had the nozzle crash into the tree support, resulting in a layer shift. The good news is that the print stayed very firmly stuck to the bed.

I’ve reset, lowered my extrusion multiplier a smidge, switched to a more traditional support pattern, and am going for it again. Wish me luck!

I guess I’m not clear what the source of ignition would be? The chamber is fairly well temperature controlled, so it’s not likely that something inside will overheat. The cloth that’s draped over outside of the printer can’t come into contact with any hot bits thanks to acrylic panels. The chamber itself is currently sitting at 59 C after the print has been going for 10 hours (plus 1.5 hours of preheat before that).

Agree on venting, I need to duct my exhaust fan to the outside.

A space blanket is a good idea. I have a few lying around and will add one. Bonus points for being a radiant barrier (eg should help get things warmer again). I’m surprised that mylar will help prevent the spread of fires.

All the electronics inside are very much capable of combustion.

Your power supply inside the printer body for example can very much fail and burst into flames.

And tbh it’s not that uncommon for that to happen with 3d printers. They’re often made with very cheap parts and prone to cheap work on the inside bits.

Add on how much of a high wattage load they meed to handle for extended periods of time and yeah, sometimes the inner wiring bursts into flames and the whole thing goes up.

I always recommend keeping a cheap lil smoke alarm directly overhead any 3d printer, seriously. Those fuckers can very much spontaneously burst into flames lol

The electronics are housed in a (reasonably) sealed airspace below the print bed and have two fans blowing across them. Here’s a link to CAD/STLs/some pictures: https://vorondesign.com/voron2.4. If you want to poke around GitHub, you can do so here: https://github.com/VoronDesign/Voron-2. No printer is perfect, but Vorons are fairly well thought out and I didn’t skimp out on components when I was sourcing parts. All wiring inside the enclosure is either PTFE or silicone insulated.

Here’s what it looks like underneath:

Totally covered.

Well, you’ve just decommissioned my printer until I’ve changed the smoke detectors batteries